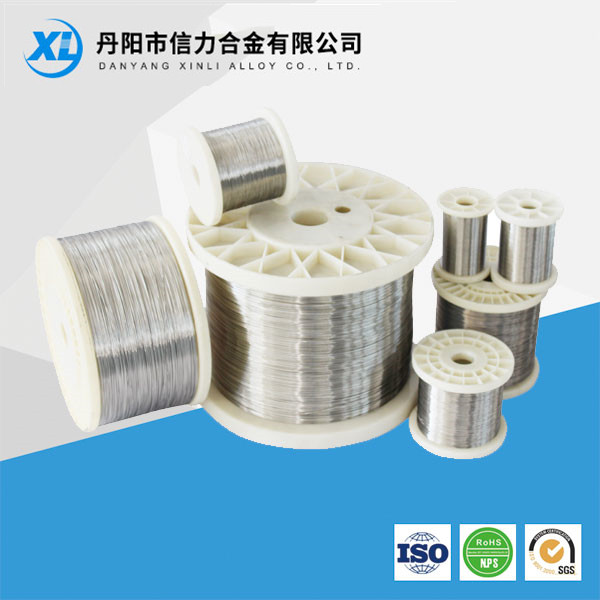

GH2132 Oxidation-resistant Alloy Steel

1. Standard: GB/T14992-2005

2. Size: 0.4 ~ 4 * 1000 * 2000 mm

3. Chemical Composition:

Ni: 24-27; Cr:13.5-16; Fe: balance ; Mo:1.0-1.5; P¡Ü0.015 ; V:0.10-0.50; C:¡Ü0.08; Mn:¡Ü0.35; Si:¡Ü0.35; S:¡Ü0.002; Cu:¡Ü0.3; Al:¡Ü0.35; Ti:1.9-2.35

Application:Aircraft engine High-temperature load-bearing components such as turbine disks, compressor disk , rotor blades and fasteners.

4.Mechanical Properties:

Density: 7.99 g/cm3

Melting Point:1364-1424 ¡ãC

Coefficient of Thermal Conductivity (¦Ë/(W/m•¡ãC) ): 14.20 (100¡ãC).

Linear Expansibility (a/10-6¡ãC-1 ): 15.70 (20~100¡ãC )

Heat Treatment: Solution Treatment

Tensile Strength( ¦Òb/MPa ): ¡Ý 930 MPa (at 20 ¡ãC),

Yield Strength: ¡Ý 590 Mpa

Elongation( ¦Ò5 /%): ¡Ý 15% (at 20 ¡ãC),

Hardness:¡Ü341 HBS

5. Production Time: 50~60 days after getting your firm order

6. Payment Terms:T/T or L/C at sight.