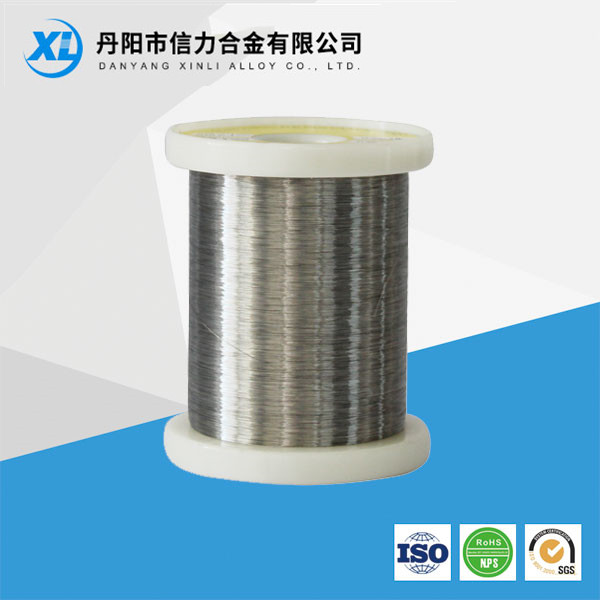

Nimonic 80A alloy is a wrought, age-hardenable nickel-chromium alloy,strengthened by additions of titanium, alunimum and carbon, developed for service at temperatures up to 815¡æ(1500¨H). It is produced by high-frequency melting and casting in air for forms to be extruded. Electroslag refined material is used for forms to be forged.

Vacuum refined version are also available. Nimonic 80A is currently used for gas turbine components(blades, rings, and discs), bolts,nuclear boiler tube supports, die casting inserts and cores, and for automobile exhaust valves.

Chemistry

| ¡¡ |

Cr |

Ni |

Ti |

Co |

Al |

Cu |

B |

| % |

18.0- 21.0 |

Balance |

1.8- 2.7 |

2.0 max.. |

1.0- 1.8. |

0.2 max. |

0.008 max. |

| Zr |

Pb |

Mn |

Si |

C |

S |

Fe |

| 0.15 max. |

0.0025 max. |

1.0 max. |

1.0 max. |

1.0 max. |

0.015 max. |

3.0 max. |